New Voice Assistant for Production Works According to the Rules of Ai Ethics

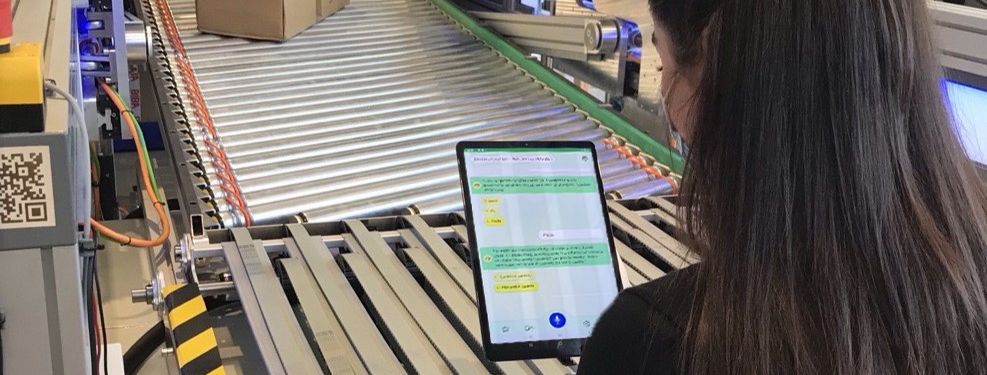

Quick help even with complex problems: In future, an intelligent voice assistant will be able to help people in production. The COALA project relies on the trustworthy use of artificial intelligence. The system can support the work, training and knowledge transfer of employees via smartphone or tablet and reduce costs and time. This is the result of the COALA R&D project with 14 partners from 5 nations. BIBA - Bremer Institut für Produktion und Logistik was responsible for coordinating the 5.7 million euro EU project.

Transparency and protection of employees and companies - the use of artificial intelligence (AI) in management and production processes is increasingly raising ethical questions. AI ethics was a key focus of COALA research and development. The COALA project partners are confident that their system is one of Europe's first trustworthy digital voice assistants for the manufacturing industry. They have made the project results available at Zenodo, an open repository that can be used primarily for storing scientific data sets, and at the European AI community via the AI4Europe platform, for example.

The COALA solution is based on the privacy-focussed open assistant Mycroft. Among other things, it enables the rapid generation of data analyses and the provision of information for individual workstations based on the company's complex, distributed data.

The COALA assistant is also supported by a new type of explanatory software, the WHY engine. It enables the assistant to explain its predictions. This enables users to better understand why and on what basis the assistant has given a certain answer.

Benefits for vocational training too

Another important pillar of the project was the successful application of the voice assistant in vocational training. To achieve this, a didactic concept was developed by the Institute of Technology and Education (ITB) at the University of Bremen using the textile industry as an example. The on-the-job training assistant shortens onboarding times for new staff and also supports the transfer of implicit knowledge. A user-defined dialogue model and the cognitive advisor service make it possible to determine the worker's current level of knowledge and advise them on preparing and operating a machine, for example.

Three use cases analysed

The consortium researched and developed three exemplary use cases from the textile, chemical and white goods industries: at the production sites and with data from the project partners Fratelli Piacenza (Italy), Diversey Netherlands Production (Netherlands) and Whirlpool Management EMEA (Italy). The Biella Textile Academy (Italy) was also involved with its wide range of training programmes for skilled workers.

Result: Partly "significant improvements“

Among other things, COALA helps to simplify and speed up training times on machines and systems and to avoid quality problems. According to projections based on the field test at Whirlpool, defects identified with COALA support can be reduced by more than 50 per cent in some cases. Due to a lower number of calls per plant and a lower number of service calls to end customers, the company was also able to achieve a 20 percent reduction in organisational costs in this area with COALA.

In addition, evaluations at CittaStudi (Textile Academy) showed a significant improvement in task performance by 42 per cent compared to the basic scenario without COALA. The COALA assistant implemented at project partner Diversey achieved the highest value in the transfer of implicit knowledge according to the field tests and evaluations, followed by a 30 per cent reduction in the time required to process problems and a 50 per cent reduction in training time.

Key data on the COALA project

The 3-year COALA project (COgnitive Assisted agile manufacturing for a LAbor force supported by trustworthy Artificial Intelligence) project involved 14 research and industrial partners from five nations. They come from Italy, the Netherlands, Greece, France and Germany. The consortium, led by BIBA - Bremer Institut für Produktion und Logistik at the University of Bremen, has developed a voice-based digital intelligent assistant for industry that supports workers in production and can be used via smartphone or tablet, for example. A particular focus of the research was on the trustworthy use of artificial intelligence in accordance with the guidelines of AI ethics. The project was funded by the EU with 5.7 million euros.