UNITED GRINDING Presents a New Automation Solution

The UNITED GRINDING Group presented a new automation solution in the field of tool machining at this year's GrindingHub. The trade show appearance was held under the theme "Stay Connected" and focused on connectivity solutions.

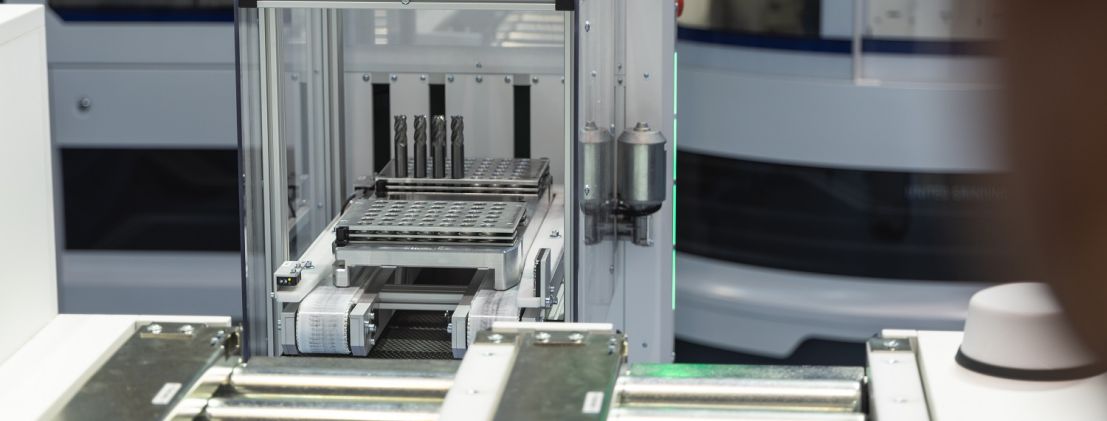

Numerous visitors gathered at the UNITED GRINDING Group's trade show booth on the first day for the unveiling of the WALTER innovation. At 10 a.m., the covers came off, revealing a mobile transport robot that moved autonomously between the HELITRONIC VISION 400 L high-end tool grinding machine and the fully automatic HELICHECK PLUS measuring machine. This innovative automation solution under the name "Automated Tool Production" (ATP) enables the automatic loading and unloading of cylindrical precision tools. The system consists of at least one robot cell accessible from the front and a mobile transport robot that transports workpiece pallets and individual parts between the storage and processing stations. The new system can be integrated easily into existing installations, not only to WALTER machines but also to machines from third-party suppliers.

In addition, WALTER surprises with another innovation and opens a new chapter in the history of tool machining by introducing laser technology based on the new VISION LASER machine. The main application area for the new machine is machining cutting tools with inserts. Using an innovative, highly reliable, and industry-proven laser system paired with encapsulated optical modules enables very high machine availability in everyday operation.

Development of the Group's Business

The UNITED GRINDING Group also held a press conference at GrindingHub, at which Stephan Nell, CEO of the UNITED GRINDING Group, provided insights into the state of business. Nell stated, "The past year was one of the three best in the history of our Group," surprising the audience, consisting of invited representatives of the international trade press. Despite the challenging economic and geopolitical climate, the Group not only maintained its market-leading position in 2023 but also expanded it. However, the outlook for 2024 is less rosy for the industry: "Like the entire machine tool industry, we also have to expect a decline in sales in the current year," explains Nell. However, forecasts are difficult due to the unpredictability of global events. "We have little or no influence on the external factors that are currently shaping the market. Different dynamics within the regions and industries are making forecasting even more difficult. Overall, we are hoping for an increase in incoming orders towards the end of the year," concludes Nell, giving a cautiously optimistic outlook for the future.

Stephan Nell also mentioned, based on an external market analysis, a regional shift in the market volumes in machine tools. From a global perspective, a decline can be observed in China, while the proportionate volume in North America is growing. In Asia, excluding China and Europe, the relative market volume is currently changing only slightly. Within Europe, on the other hand, there is a clear shift from the DACH (Germany, Austria, Switzerland) region to Eastern Europe. Central Europe is only losing a little in terms of relative market volume. “As a Group, we are also very aware of these shifts in volume and demand,” says Nell. “In addition to our traditional home markets of Europe, particularly the DACH region, North America, and China, we are therefore intensifying our activities in South East Asia and have established a group branch office in Singapore. Eastern Europe has also moved into our strategic focus. We already intensified our sales activities there some time ago,” Nell continues, concluding his remarks with the words: ”We will gradually expand the regional diversity of our Group, which has always been one of our great strengths, to remain close to our customers in the future and maintain the Group's stable base. Based on how we are underway, I am optimistic about the future.” Only a strong Group can fulfill its paramount goal: To make its customers even more successful.