Nikon Launches VOXLS 20 C 225 for Industrial CT Inspection

Nikon has unveiled the VOXLS 20 C 225, a new compact addition to its industrial X-ray CT product line. Designed for advanced quality control, the system combines high-end scanning capabilities with a footprint that fits through a standard double door. This enables seamless integration into labs and production environments where space is at a premium.

The VOXLS 20 C 225 is built on the same technical foundation as Nikon’s VOXLS 30 and 40 Series, but its smaller form factor makes it a more versatile option for space-constrained settings. The system offers an impressive inspection volume of 555 mm in diameter and 759 mm in height, housed within a chassis just 2451 mm long and 1173 mm deep. It delivers excellent voxel resolution and data quality for demanding industrial applications.

The CT scanner is engineered on Nikon’s metrology-grade platform with a granite base and rigid steel manipulator towers. High-precision encoders and motors ensure accuracy and repeatability, delivering the imaging quality and operational reliability required in critical inspection workflows.

Industry-Leading Scan Volume in a Compact System

Despite its compact footprint, the VOXLS 20 C 225 offers a scan envelope large enough to accommodate complex and sizable components. This makes it well-suited for high-value industries such as aerospace, medical devices, additive manufacturing, and automotive, where internal structural integrity is paramount. The system’s dual-source configuration allows automatic switching between a 225 kV reflection target and a 160 kV transmission target. Operators can easily select the optimal source based on inspection requirements: higher flux for speed or higher resolution for detail. This not only improves inspection throughput but also eliminates manual source adjustments. To simplify maintenance and improve uptime, Nikon has included a filament optimization feature that streamlines setup, prolongs filament life, and simplifies replacement.

Designed for Operator Efficiency

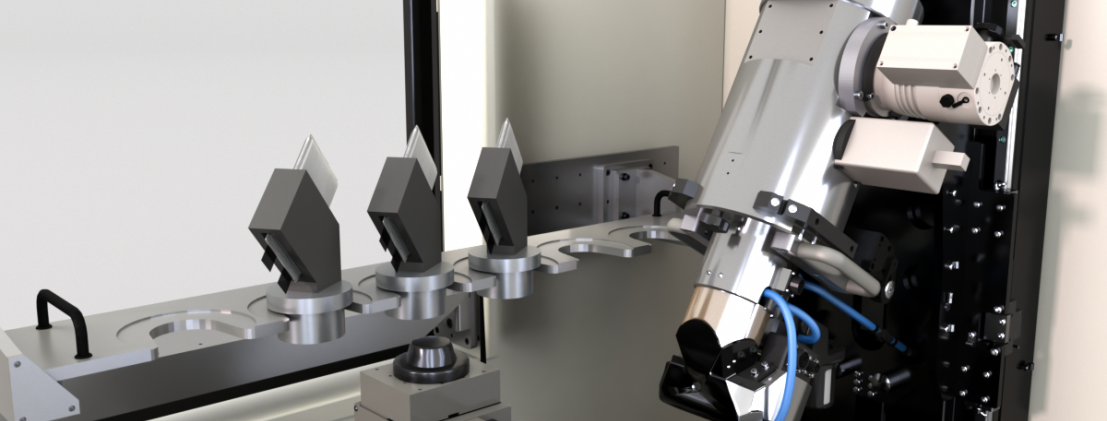

The VOXLS 20 C 225 emphasizes usability with features such as a rapid-opening motorised door, a large viewing window for interior visibility, and an automated filter changer. Advanced scanning techniques—Motorised FID, Panel Shift CT, Tilted CT, and Pixel Split CT—are supported, enabling a wide range of inspection geometries and part types. The system also incorporates Nikon’s latest innovations, including X.Tend Helical for extended scan ranges, Scatter Correction CT to enhance image clarity, and AI Reconstruction for accelerated data processing. It supports future integration with Nikon Automation through an OPC UA interface, making it adaptable to robotic inspection environments and automated workflows.

The first shipments of the VOXLS 20 C 225 are expected in autumn 2025. Nikon positions the system as a long-term investment that meets the evolving demands of advanced manufacturing. With its compact footprint and scalable architecture, it is engineered to perform reliably both in the lab and on the production floor.

Related posts

Currently there are no news items.