IMTS 2022 address manufacturing’s biggest challenges

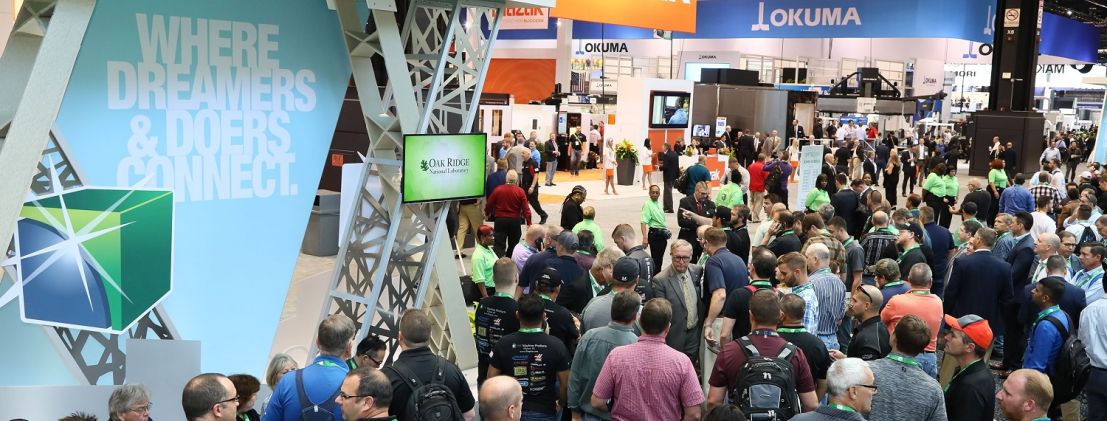

Manufacturing is back, and Chicago will be the epicenter, as an estimated 90,000 people will attend IMTS – The International Manufacturing Technology Show, which runs from Sept. 12-17 at Chicago’s McCormick Place. IMTS is the largest manufacturing technology show in North America. With more than 1.21 million square feet of exhibit space representing 1,815 exhibitors, the show features digital technologies that offer the fastest and most efficient means of solving the challenges faced by manufacturers and their suppliers.

Nine technology pavilions feature solutions such as multi-tasking machining centers, robots/cobots, digital twin, manufacturing software, controls, additive manufacturing, and quality control/inspection. More than 75,000 people have preregistered for the show, which attracts OEMs, tier suppliers, contract manufacturers/fabricators, jobs shops, sourcing/purchasing agents, investors, students, and technical educators.

“The advances in digital manufacturing technology on display at IMTS 2022 will amaze even industry veterans,” says Peter R. Eelman, chief experience officer at AMT – The Association For Manufacturing Technology, which owns and produces IMTS. “If OEMs and job shops can digitize it, they should. Digital tech is the best way to increase productivity with an existing talent pool, control costs, make reshoring/near-shoring more attractive, reduce time to market, and respond with agility to volatile markets.”

Eelman notes that the affordability and ease-of-implementation now puts advanced solutions within reach of small and medium-sized businesses.

“IMTS exhibitors have blown away existing barriers to technology acquisition,” says Eelman. “For example, visitors can learn how to set up and run an entry-level automation solution in 30 minutes. Computed tomography inspection systems now operate with almost push-button simplicity, and digital twin technology is as easy to use as your favorite CNC control or CAD/CAM program.”

Related posts

Currently there are no news items.