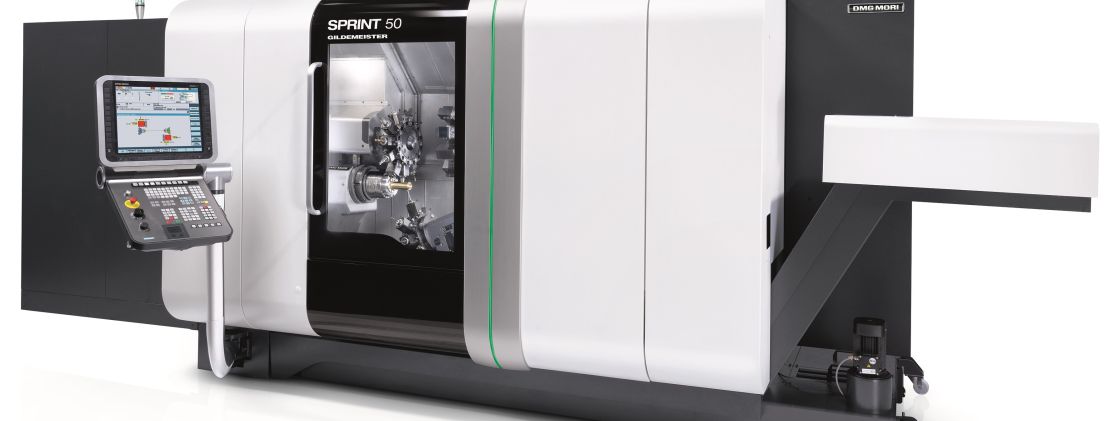

DMG MORI automatic lathe provides productive bar machining with 3 turrets and b-axis

The DMG MORI SPRINT 50, an automatic CNC lathe equipped with three turrets and the B-axis, makes its Asia premiere at JIMTOF2014. The SPRINT 50 is equipped with three turrets, of which the lower turret has a B-axis - unique for automated production turning machines. Three turrets allow highly productive machining of short workpieces and collision-free machining with three turrets on the main and counter spindle. The swivel range of the B-axis on the lower turret from –23.5 to +158.5 degrees allows machining of negative angles with cost-effective standard tools.

Alternatively, the SPRINT 50 can also be equipped with three turrets without a B-axis. In the cost-effective entry-level option, the machine has two turrets, including the patented and thousand-fold proven TWIN concept. This unique work area concept with two turrets and the cross traverse of the counter spindle-tailstock combination allows parallel machining in two independent work areas.

Highly efficient production turning

The focus of the SPRINT 50 is on highly efficient production turning in serial production. The 12-fold VDI 25 turrets with TRIFIX are consistently equipped with driven tool stations and offer speeds of up to 8,000 min-1 (6,3 kW, 12 N・m). The TRIFIX precision quick change interface for set-up times of less than 30 seconds and repeatability of 6 µm. is also standard. The application field of the SPRINT 50 models is complete machining of bars up to Ø 50 mm in diameter.

The ergonomically designed SPRINT 50 offers perfect accessibility and maintainability. The distance between the machine front and the turret has been reduced by 70 percent to 400 mm for easier setup operations. Despite its wide machining area with a B-axis swivel range of 182° (-23.5°/ +158.5°), the SPRINT 50 has achieved a compact footprint of 9.6 m2 (including a chip conveyor), thereby dramatically increasing productivity per unit area. Additionally, steep, low-maintenance covers made of stainless steel are used in the machining area for better chip disposal and from standard equipped for wet, oil and dry machining, while all hydraulic units are located in one place for better access and easier maintenance.

As for the machine construction, DMG MORI employed a vertical cast iron bed to achieve superior rigidity and thermal stability. The highly rigid bed allows for stable machine installation with three-point support. The three-point support installation is less susceptible to ground conditions or secular change and enables easier level adjustment and much faster installation work.

Related posts

Currently there are no news items.